The F-15 uses a very interesting system for the roll and pitch control – it’s both Fly by Wire and mechanical interconnect.

If you were to pin the stick in place with your knees, you can fly the jet by pressure on the grip all by itself, just like an F-16.

The magic for this happens in the little box that the stick grip attaches to. This box is known as a Stick Force Sensor:

This box holds a load cell beam, very similar to the one in the base that the flight grip of the F-16 plugs into. This load cell is what translates the stick force into electrical signals that the on-board computer translates into control surface movement.

The lever in front of the grip base is the Auto Pilot/Nosewheel Steering disconnect. If you’re on the ground, it disengages nose wheel steering – the red button in the picture next to the lever engages the nose wheel steering. If you’re in the air, the lever will disengage the autopilot.

Because of how important this little box is to my project, I’ve probably got more dimension data than any other part in the whole cockpit.

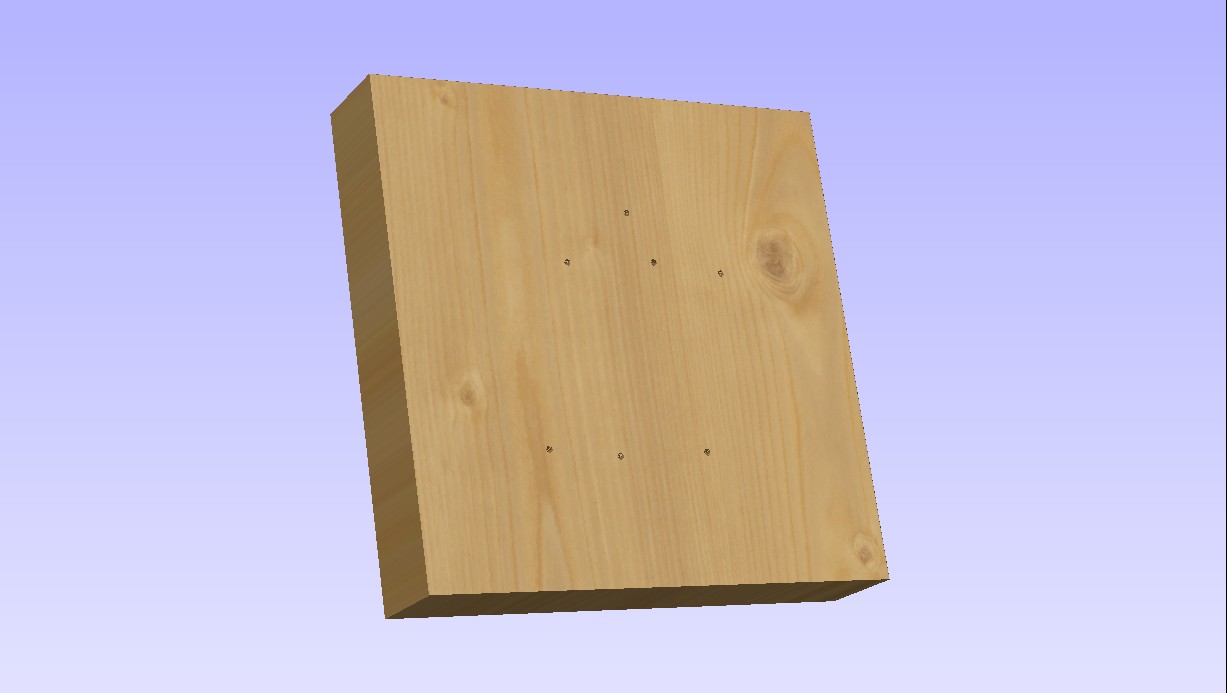

This week I’ll be making one on the ShopBot. The following images are renderings from the software that I use for creating tool paths for parts to be cut on the ShopBot. The base material is a 10″ x 10″ laminated plywood block, 2″ thick.

First up, the drill holes:

Six mounting holes and the hole for the hinge pin for the AP/NWS disconnect lever.

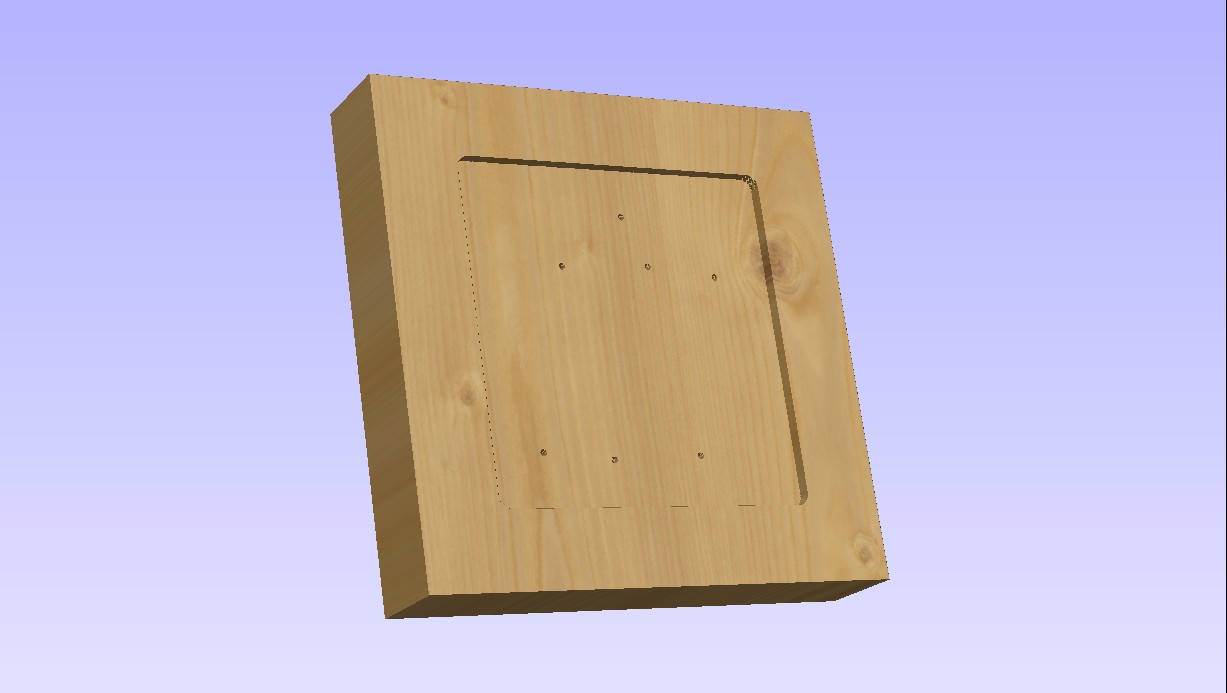

Now it gets machined down to 1.75″ thick:

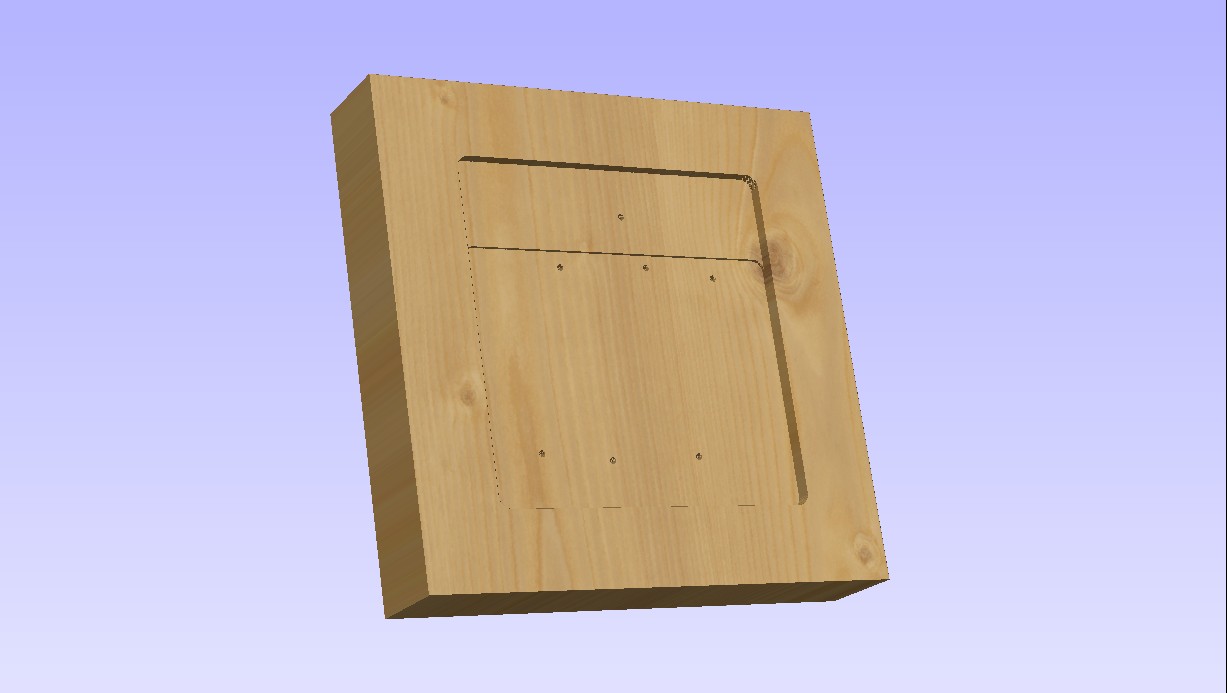

Now it gets cut down a bit more to make room for the .062″ thick aluminum box cover:

This will result in a different look to the SFS box and I may change it before I cut material.

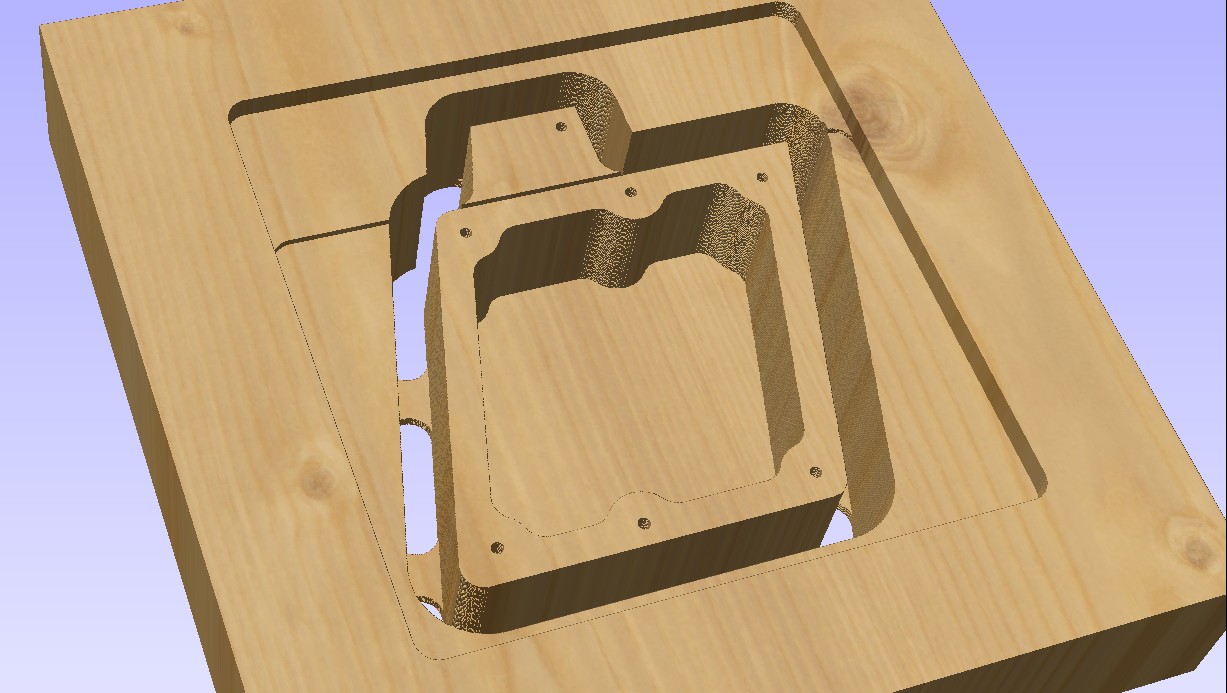

Now we create the main interior pocket for the box:

…and finally it’s time to cut the box shape out:

The tabs hold the box into the base material so it won’t shift during cutting. The box will be complete after the sides of the AP/NWS area are shaped to more closely resemble the original.

All the cutting will be done with a .50″ downshear end mill with a 1.75″ cutter length. (The tool itself is 4″ long)

Comments

Leave a Reply

Gary Hall on 07.02.2017

Good afternoon…

I am curious if you would mind sharing some of the dimensional drawings of the SFS box. I would like to see if it is possible to have one 3d printed to use with a Suncom Stick and TM Warthog Components.

Thanks in advance

Gary