January 25th, 2003

The original throttle control interface that I designed turned out to

be an almost-ran. The problem was that the slide potentiometers that I

obtained for the mechanism weren't long enough. I had incorrectly measured

the pushrod travel and it turned around and bit me.

After many months of avoiding the problem entirely, I decided it was time to

deal with it and get it over with. I went shopping for slide pots that

would be large enough to do the job. Boy was I in for a shock. For the

size that I needed (a minimum of 5.50" of travel) I would be looking at

spending nearly $130 each. Thanks, but no thanks. There's got to be a

better way.

After some careful thought, I designed a replacement mechanism that would

utilize standard rotary pots instead of the slides. They would have gears

mounted on them and be driven by a pair of metal racks. After consulting a

few friends on how to calculate the correct gear size, I ordered a pair of

gears and a pair of 12" brass racks from Small Parts

Small Parts is a neat place to find things like gears and mounting hardware

but they offer nothing in technical assistance, so you'd better know what

you're buying before you place your order.

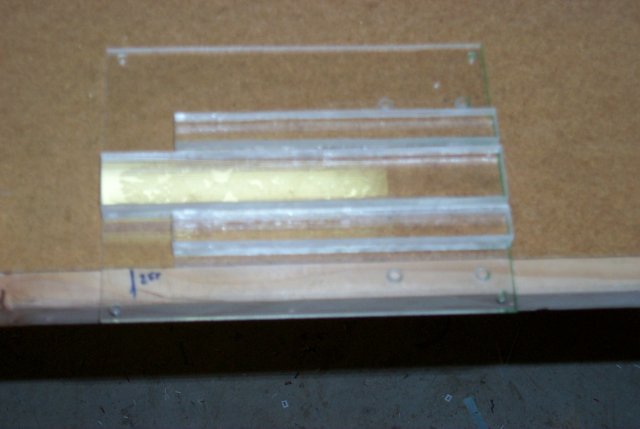

The original mounting plate was made of 1/16" aluminum and would flex too

much under the loads the new design would experience. Since I had a pile of

acrylic samples that I'd purchased earlier in the year, I decided to use that.

I created a base plate of the same dimensions as the earlier metal version

out of 1/8" stock. I then created three "rails" by bonding two layers of

1/4" acrylic together. This in turn was glued down to the base plate.

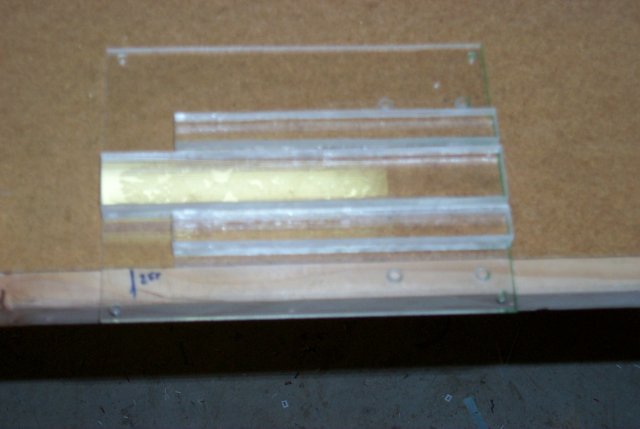

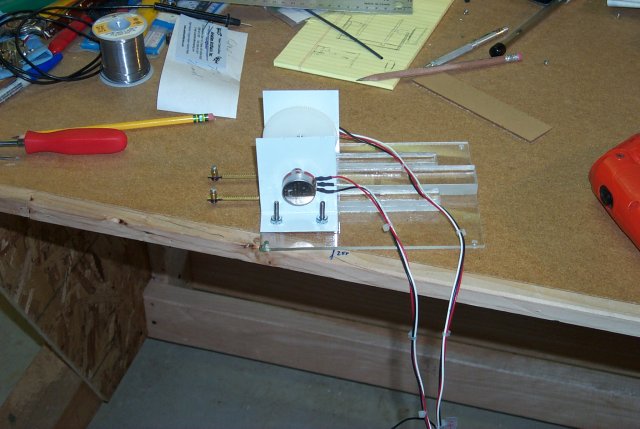

This is the finished base plate. I decided not to paint it since it looks

more interesting as a clear assembly.

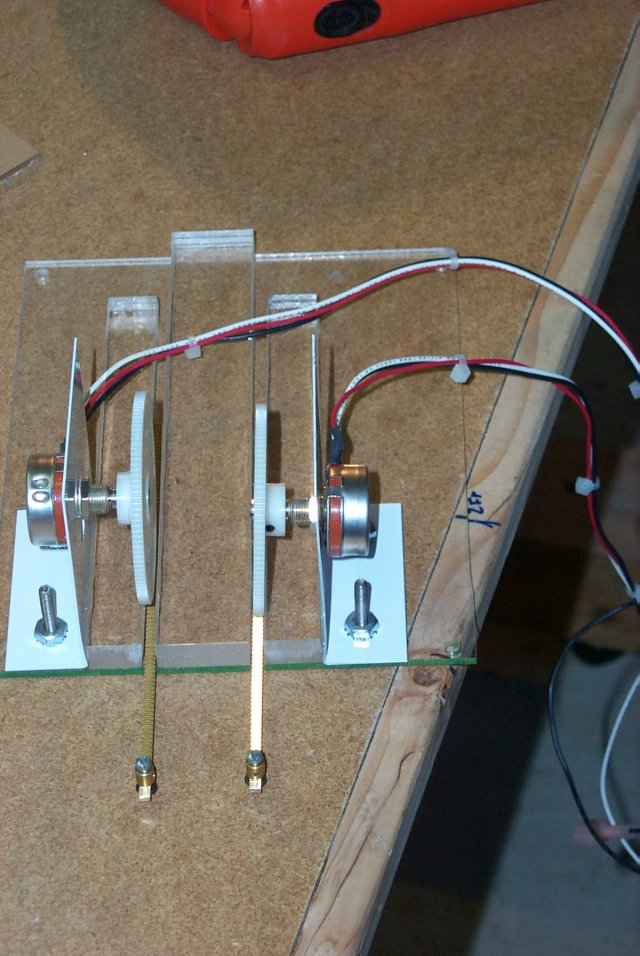

Below you can see the finished result.

This is the finished base plate. I decided not to paint it since it looks

more interesting as a clear assembly.

Below you can see the finished result.

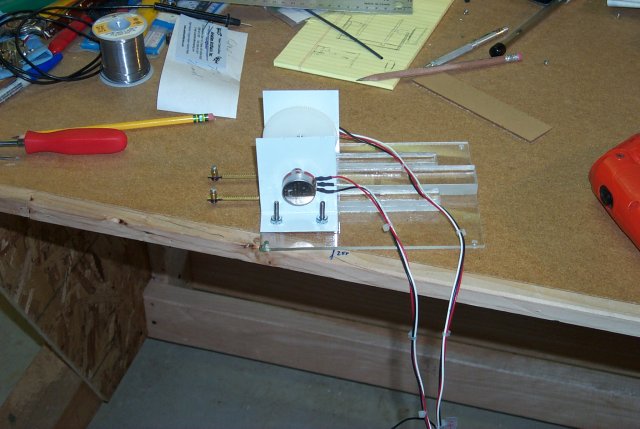

Here is an extreme close-up:

Here is an extreme close-up:

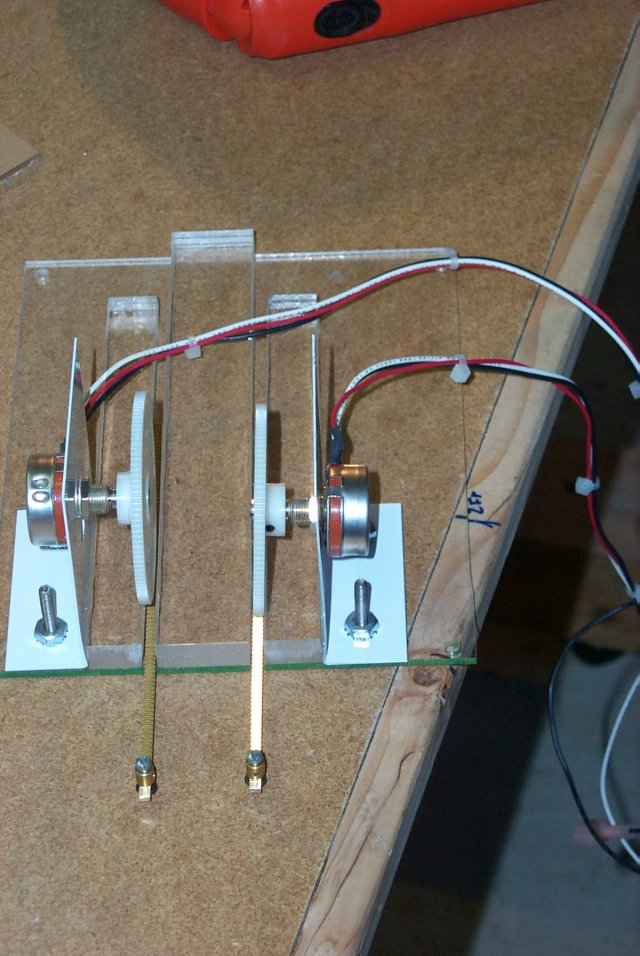

The pots are high-precision 100K Ohm rotaries. Since they're high-precision

they won't withstand the cycle count that a more robust part could handle,

but they'll last until I can replace them with an equivalent rotary Hall

Effect Device like the ones being used in the Thrustmaster Cougar refit

kits.

The racks are 1/8" wide brass with Du-Bro pushrod keepers attached to the

ends. It turned out after installation that these keepers were too wide so

they were replaced with a pair of Sullivan clevises that I ground down to

a width of .051".

The metal mounts for the pots are drilled in such a way to allow me to

adjust the tension that the gear exerts upon the rack. It's a trick to get

it adjusted correctly. You'll note that the right gear is at a bit of an

angle. This was corrected.

The installation was fairly painless once the fit & finish issues were

resolved - the racks needed a bit more room cut into the base plate to

prevent jamming on the edge.

The pots are high-precision 100K Ohm rotaries. Since they're high-precision

they won't withstand the cycle count that a more robust part could handle,

but they'll last until I can replace them with an equivalent rotary Hall

Effect Device like the ones being used in the Thrustmaster Cougar refit

kits.

The racks are 1/8" wide brass with Du-Bro pushrod keepers attached to the

ends. It turned out after installation that these keepers were too wide so

they were replaced with a pair of Sullivan clevises that I ground down to

a width of .051".

The metal mounts for the pots are drilled in such a way to allow me to

adjust the tension that the gear exerts upon the rack. It's a trick to get

it adjusted correctly. You'll note that the right gear is at a bit of an

angle. This was corrected.

The installation was fairly painless once the fit & finish issues were

resolved - the racks needed a bit more room cut into the base plate to

prevent jamming on the edge.

You can see how the pushrods connect to the racks. It's amazing how

applicable model airplane hardware can be in a home-built flight simulator!

You can see how the pushrods connect to the racks. It's amazing how

applicable model airplane hardware can be in a home-built flight simulator!

The only thing I'm really not happy with is all the open space between the

pushrod exits and the leading edge of the mounting plate. I don't think the

racks have enough support. I'm hoping it doesn't become an issue in the

future since there is little room to work in there as it is.

The two black tubes that are running along parallel to the throttle

mechanism are the toe brake pushrods. These are the original parts as

installed when the jet was built.

The only thing I'm really not happy with is all the open space between the

pushrod exits and the leading edge of the mounting plate. I don't think the

racks have enough support. I'm hoping it doesn't become an issue in the

future since there is little room to work in there as it is.

The two black tubes that are running along parallel to the throttle

mechanism are the toe brake pushrods. These are the original parts as

installed when the jet was built.

Back to the Tech Index

This is the finished base plate. I decided not to paint it since it looks

more interesting as a clear assembly.

Below you can see the finished result.

This is the finished base plate. I decided not to paint it since it looks

more interesting as a clear assembly.

Below you can see the finished result.

Here is an extreme close-up:

Here is an extreme close-up:

The pots are high-precision 100K Ohm rotaries. Since they're high-precision

they won't withstand the cycle count that a more robust part could handle,

but they'll last until I can replace them with an equivalent rotary Hall

Effect Device like the ones being used in the Thrustmaster Cougar refit

kits.

The racks are 1/8" wide brass with Du-Bro pushrod keepers attached to the

ends. It turned out after installation that these keepers were too wide so

they were replaced with a pair of Sullivan clevises that I ground down to

a width of .051".

The metal mounts for the pots are drilled in such a way to allow me to

adjust the tension that the gear exerts upon the rack. It's a trick to get

it adjusted correctly. You'll note that the right gear is at a bit of an

angle. This was corrected.

The installation was fairly painless once the fit & finish issues were

resolved - the racks needed a bit more room cut into the base plate to

prevent jamming on the edge.

The pots are high-precision 100K Ohm rotaries. Since they're high-precision

they won't withstand the cycle count that a more robust part could handle,

but they'll last until I can replace them with an equivalent rotary Hall

Effect Device like the ones being used in the Thrustmaster Cougar refit

kits.

The racks are 1/8" wide brass with Du-Bro pushrod keepers attached to the

ends. It turned out after installation that these keepers were too wide so

they were replaced with a pair of Sullivan clevises that I ground down to

a width of .051".

The metal mounts for the pots are drilled in such a way to allow me to

adjust the tension that the gear exerts upon the rack. It's a trick to get

it adjusted correctly. You'll note that the right gear is at a bit of an

angle. This was corrected.

The installation was fairly painless once the fit & finish issues were

resolved - the racks needed a bit more room cut into the base plate to

prevent jamming on the edge.

You can see how the pushrods connect to the racks. It's amazing how

applicable model airplane hardware can be in a home-built flight simulator!

You can see how the pushrods connect to the racks. It's amazing how

applicable model airplane hardware can be in a home-built flight simulator!

The only thing I'm really not happy with is all the open space between the

pushrod exits and the leading edge of the mounting plate. I don't think the

racks have enough support. I'm hoping it doesn't become an issue in the

future since there is little room to work in there as it is.

The two black tubes that are running along parallel to the throttle

mechanism are the toe brake pushrods. These are the original parts as

installed when the jet was built.

The only thing I'm really not happy with is all the open space between the

pushrod exits and the leading edge of the mounting plate. I don't think the

racks have enough support. I'm hoping it doesn't become an issue in the

future since there is little room to work in there as it is.

The two black tubes that are running along parallel to the throttle

mechanism are the toe brake pushrods. These are the original parts as

installed when the jet was built.