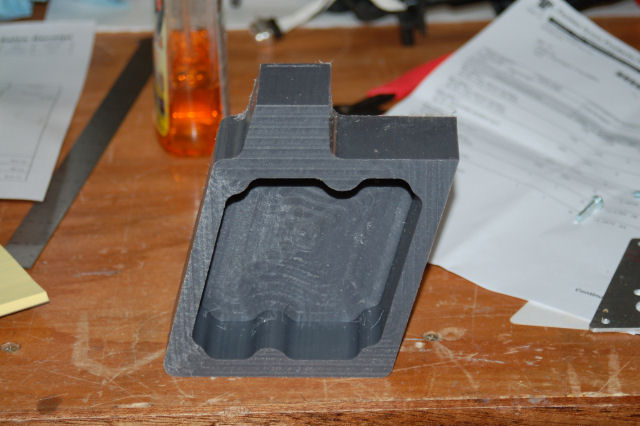

I went to my local acrylic monger yesterday and was captivated by this huge block of gray UHMW. It was _begging_ to become an SFS box.

The block was about 10 inches long, 8 inches wide and 2.5 inches thick. I needed to pare it down to 1.75″ thick first…

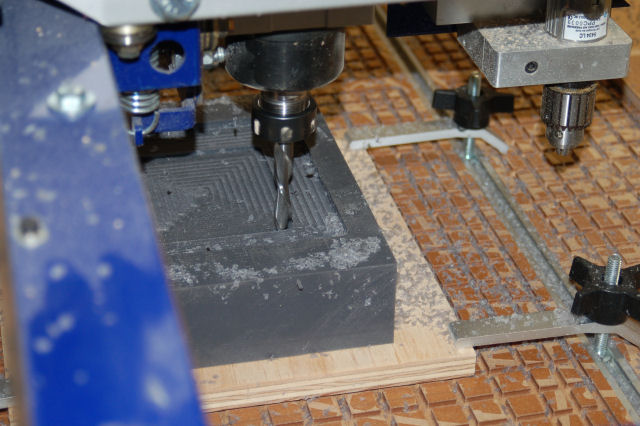

You can see the UHMW chips flying away from the cutter. I’m using a .50″ downshear cutter running at 12,000 RPM with a feed rate of 1.7in/sec. That cutter is an _animal_ in this stuff. I’ve never cut UHMW before and it was definately an experience I won’t soon forget. I’ll be cleaning up little bits of gray plastic swarf for the rest of my life I think.

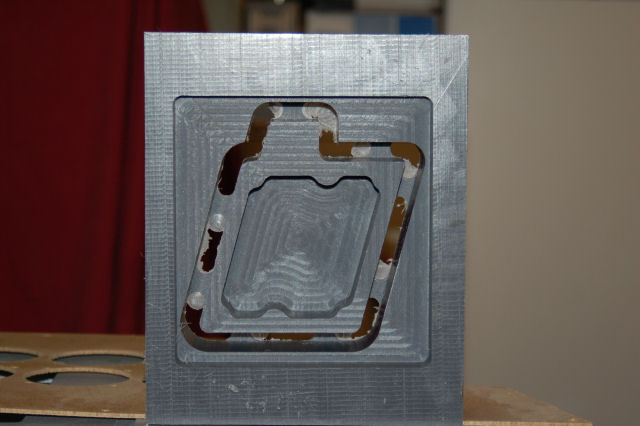

Now we get on to the interior of the SFS box…

All during the cutting process, I was trying to suck up as much of the swarf as I could with a narrow shop-vac hose. The best I could do is keep the stuff from clogging the cutter…

All done! What a f*cking mess. *sigh* The block of material has been glued down to a sheet of scrap plywood with 3M 77 spray adhesive. Worked great!

Here’s the end results:

I really don’t care for the finish the cutter left on the box so this will likely be just a fun paper weight. Tomorrow I’ll get the .062″ aluminum cover plates made…

Comments

Bre on 02.01.2010

Very cool!!!

Eric LeClair on 06.28.2016

Awesome. Love to see an update on this. I would also suggest using 3d printing with ‘Tough Resin’ by Formlabs. Great for real strong prints / home projects. http://formlabs.com/products/materials/tough/

admin on 06.29.2016

If it wasn’t nearly 3x the cost of the MakerJuice resin I have now, I might look into it. 🙂

If you rummage around the posts here, you’ll see how the SFS box ended up.