AC power is back!

I decided some weeks ago that the existing AC power infrastructure that I’d originally implemented really wasn’t going to do the job. As a result of that decision, I pulled all of the old wiring out and replaced it all with a much neater, safer, and useful configuration.

Check it out in the latest update video:

Switch gremlins fixed!

As I discovered in the last video, I had some flight grip switch problems during the testing of the new control loader.

The Castle Up switch and the “pinky” switch weren’t triggering inputs on the VPForce controller. Today I was able to tear into things and figure out what the issue is.

The good news is that the grip switches & SFS box wiring was ok.

The bad news is I had to remove the SFS cable from the cockpit in order to fix an improperly seated pin. Getting that sucker back into the cockpit took about an hour. 🙂

In order to re-install the cable, I basically nailed it in place using a copper Cleco and used a 1″ impact socket to hold down the half of a nut ring that I had for the installation.

The hard part of this process was threading the #4 screws in from below the cockpit floor while not being able to see the connector, the hole, the screw, OR the screwdriver! It took about an hour of constant fiddling, but I got it done.

I was also able to get the pitch axis tensioner pulley moved inboard the 6mm required so the belt would stop rubbing on the pulley bracket.

Hopefully, more updates next week!

Control Loader is done!

Some months ago I embarked on getting a control loader installed into the F-15C. With flight simulation and air combat “games”, it’s more commonly known as “force feedback”. While the VPForce FFB system I’m using as the base for my simulator *can* do “force feedback” things, the primary task is to provide control loading similar to what a real F-15 pilot would experience. At its most basic level, the flight control system in the F-15 will adjust the amount of force required to move the stick based on the current G loading of the aircraft. The system can require as much as 25lbs in pitch and 20lbs in roll to move the stick at high G loads. The VPForce system can’t quite hit those targets, but it’s close enough for my purposes. I don’t want to become a gym rat just to be able to enjoy my simulator. 🙂

Here’s the YouTube video I put together during the test and configuration of the system. Enjoy!

SFS Interconnect Cable is done!

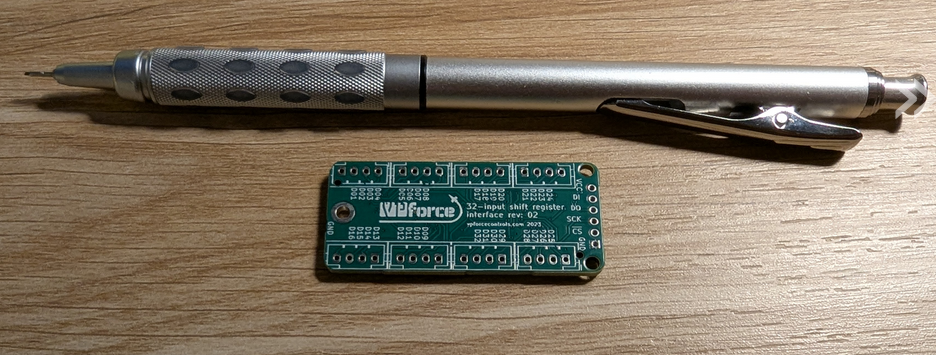

Before I can get the VPForce-based control loading system installed in the F-15, I needed to build a cable that connects the SFS wiring harness in the cockpit to something that can read the switch inputs from the grip. In this case, that device is the VPForce Shift Register board.

It’s a lot smaller than I expected. 🙂

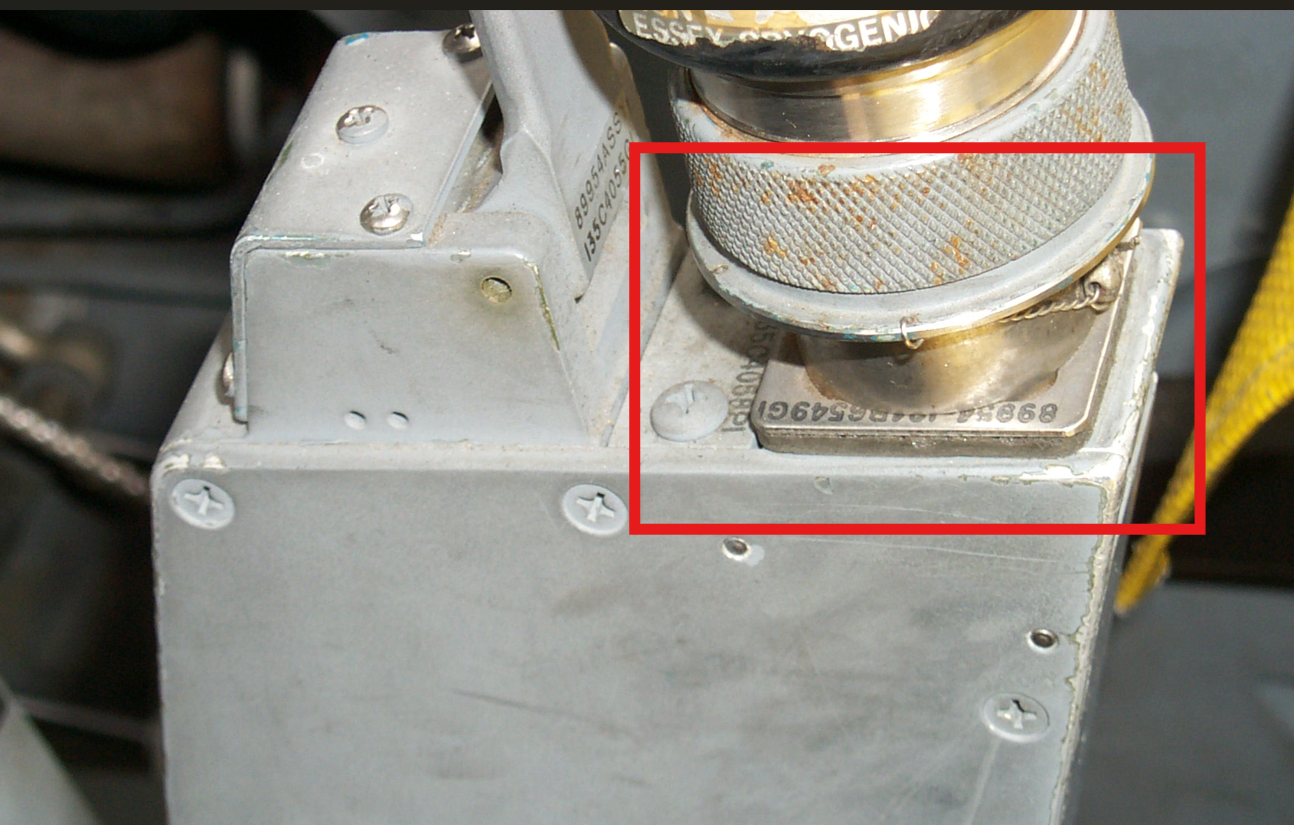

The SFS (Stick Force Sensor) box is where the flight grip is mounted. It has a post that bolts to the flight stick base in the cockpit. In a real SFS box, the grips mating plug is part of an assembly that contains a load cell. This is where the “Force Sensor” part comes into play.

You can see how I built the SFS for this project at this blog entry: https://www.f15sim.com/?p=272

Here’s the video I made that shows how the new SFS interconnect cable was made, and where it was installed. https://www.youtube.com/watch?v=8fHs_51rHa8

Holy Missing Updates!

Wow. I’ve been really remiss on posting project updates here. Let’s fix that!

Project update video in February: https://www.youtube.com/watch?v=XZFnfHmnnZc&t=19s

Last week I posted a video that covers the new control loader system I’m installing in the simulator: https://www.youtube.com/watch?v=CUWSFDEAGdQ&t=668s

The control loader is based around the VPForce Force Feedback controller and servo motors. It’s a really cool and flexible system. There’s going to be a video about that coming soon, so keep an eye out for it – subscribe to the channel if you haven’t already!

One of the things I nearly missed doing is the cable that links the SFS box & flight grip to the VPForce “shift register” board. Had I missed that, I would have had to un-install all the hardware for the control loader in order to regain access to where the cable has to go.

The cable is 1m long and has a 66 pin cannon plug on one end and will have a DB25 connector on the other. The end of the control loader video above has the details about where it’s going to go. This evening I got the sockets set into the cannon plug end, and tomorrow evening I’ll be hopefully finishing it up.

The magnifier is basically required these days! 🙂

More soon! Thanks for taking the time to stop by and check out the site.

New ACES II decals!

I posted a short video yesterday that covers the new ACES II decals that I bought from Invictus Cockpit Systems (https://invictuscockpits.com/). I also covered a bit about how the VPForce FFB system is going to connect to the existing flight controls, as well as the apparent broken-ness of the inertia reel assembly in the ejection seat.

New handles installed!

I was finally able to get the last of the work done installing the NOS ejection handles into the ACES II ejection seat. Most of the delay was due to the high temperatures in the area of late – it really limits the amount of time I can spend in the workshop, unfortunately.

Ejection Seat Woes, Begone!

Well after dithering about how to “correctly” solve the issue with the NOS initiator handles in my ACES II seat, I finally got off the dime and removed about 10mm of material from the front of the handle well.

With that done, I was able to re-install the spring mechanism that connects the handle to the torque bar. The torque bar spans the seat width and connects the two handles together.

There’s two things left to do right now – I need a spring compressor in order to collapse the spring enough that I can install the retaining pin at the top end of the guide rod. I’ve also got a temporary fastener installed on the bracket attached to the torque rod. That has to be replaced with the original 10-32 bolt. Once that’s done, I can repair the other side!

Next steps will include dumping the spring into rust remover and getting the latching/guide mechanism that’s under the seat pan cleaned up and re-installed. I’ll be posting a video about this soon.

Force Feedback & 3D Scanning!

In this video I cover the components of the VPForce FFB system I’m going to use and doing the 3D scanning needed in order to design the components for the system.