In this video I cover the components of the VPForce FFB system I’m going to use and doing the 3D scanning needed in order to design the components for the system.

Fresh off the camera. 🙂

This weekend saw a bunch of “non-F-15” work done in the shop. I spent Saturday working on the PrintNC project – I bought some “pcnpro” parts that consist of machined aluminum parts for the X & Y roller assemblies. I also previously purchased some replacements for the X & Y roller steel that weren’t cut as square as they needed to be.

In my rush to get the new parts marked & drilled, I got my X & Y axes mixed up and drilled the wrong holes in the X axis roller beam. (That’s a 90mm long bit of 3×2″ steel box beam.), so I had to cut a new one. In order to do that, I had to unbox and set up the new horizontal band saw that I bought. That was originally purchased in order to make parts that I needed for the new canopy hinge support. It took me a while to get the thing dialed in – I’ve never used a metal cutting bandsaw before. It started out making pretty bad cuts – thicker on the bottom than on the top. I sped up the blade and adjusted the force applied so that it cut slower. I got a good enough result after a few iterations that I was able to cut a new bit of steel for the X axis roller beam part. All three parts (2 Y axis roller beams and the 1 X axis roller beam) have been drilled, tapped, and painted. I’m waiting for some new fasteners to show up so I can install them. The “supplied” fasteners are socket head cap screws, and button head screws should really be used to mount them to the HGR carriages. There will be a rant about this when I do the “post mortem” video of the mechanical assembly.

I ordered a 14″ diameter Lazy Susan bearing today in order to build a multi-use platform. The first use will be to support the ACES II Ejection seat while I work on it. I’ve got it up on my main work table so having it on a Lazy Susan will make it easier to work on, and it won’t scratch the shit out of the table when I move it. 🙂

As to the ejection seat, it’s been positively identified as some kind of training device. I got some great feedback from an employee of the company that manufactures them. The number of real components leads the individual to believe that it was originally designed as some kind of procedures trainer for pilots. Investigation of its origins are still ongoing.

I’m going to try to update this site with weekly updates. We’ll see how well that works. 🙂

Here’s a link to some photos I took of the seat right after I got it “unboxed”.

This page can also be found on the Technical tab above.

Getting a real ACES II ejection seat for the F-15C has been a dream since I got the cockpit section. It took 23 years to do, but I finally got my hands on one!

Check out the “unboxing” video below:

Fortunately it’s not missing critical bits and should prove fairly easy to restore.

I just dropped a new video that covers the re-launch of the project. It’s time to get shit done.

Check out the Library tab above – I’ve scanned the complete mishap report as I received it from the USAF in 2004.

This took a completely unacceptable time to finish. 🙁 I tore down the original panel probably close to three years ago. Life and other projects conspired to push work on the F-15C to the background. Yesterday (9/19/20) I got out of bed with my task for the day to get this panel knocked out. I didn’t get it done in a single day, but damn near. 🙂

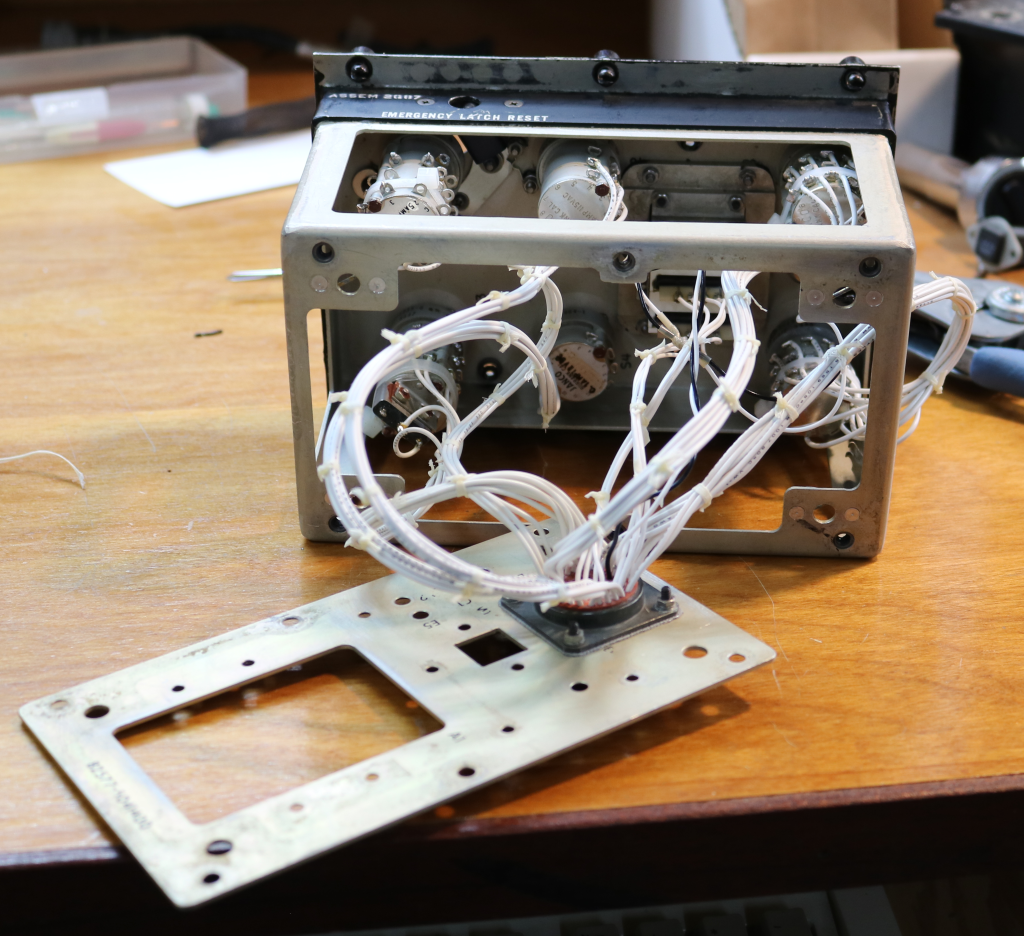

I disassembled the APG-70(V) radar panel and stripped down all the switches of the original wiring and carefully de-pinned the Cannon connector. I worked out the connection positions on the switches and got new leads attached. When I originally started this rebuild, I got as far as a single switch and then SQUIRREL!…

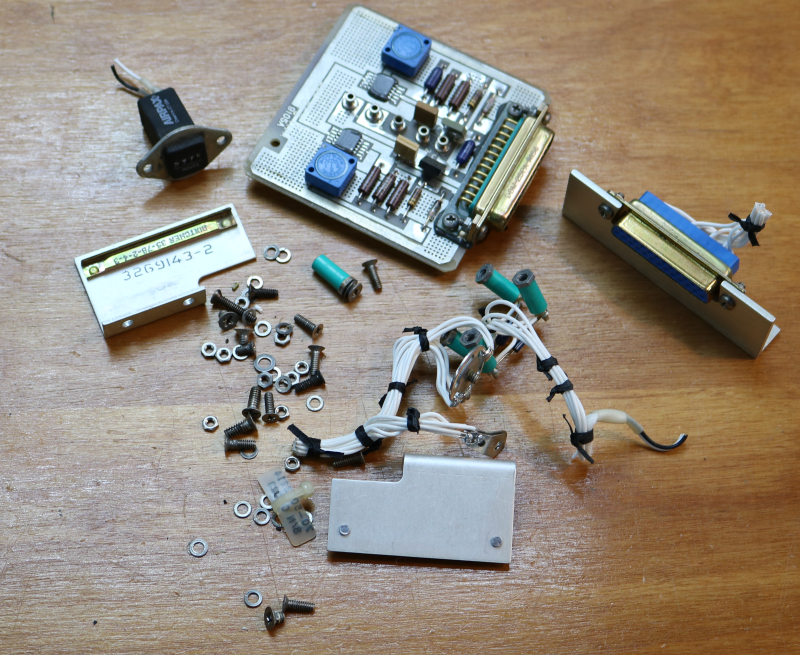

Here’s what the panel components look like prior to final assembly:

And after installing & pinning the interface connector:

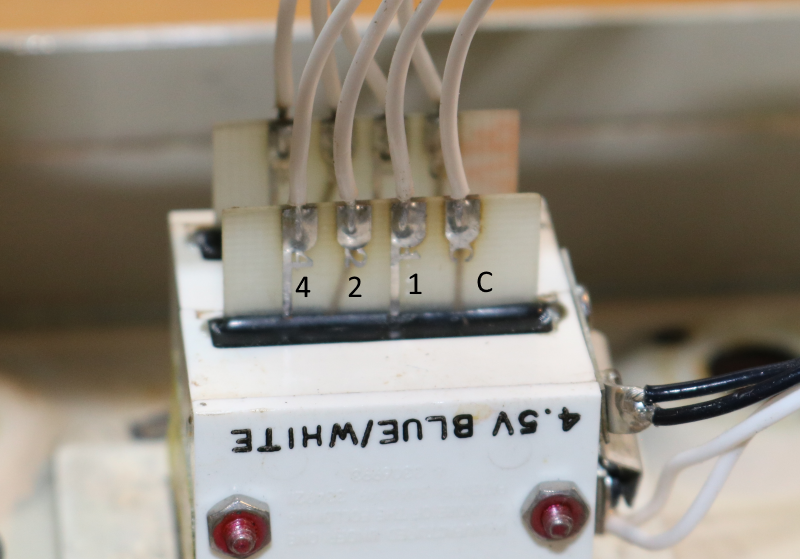

The channel selector is kind of a neat switch. It consists of two 8 position rotary switches. The first is labeled “A” through “H” and the second is “1” through “8”. The switches are BCD – Binary Coded Decimal. There’s a common wire on each and then three terminas, “1”, “2”, and “4”. Those three wires in combination can represent 8 different switch positions.

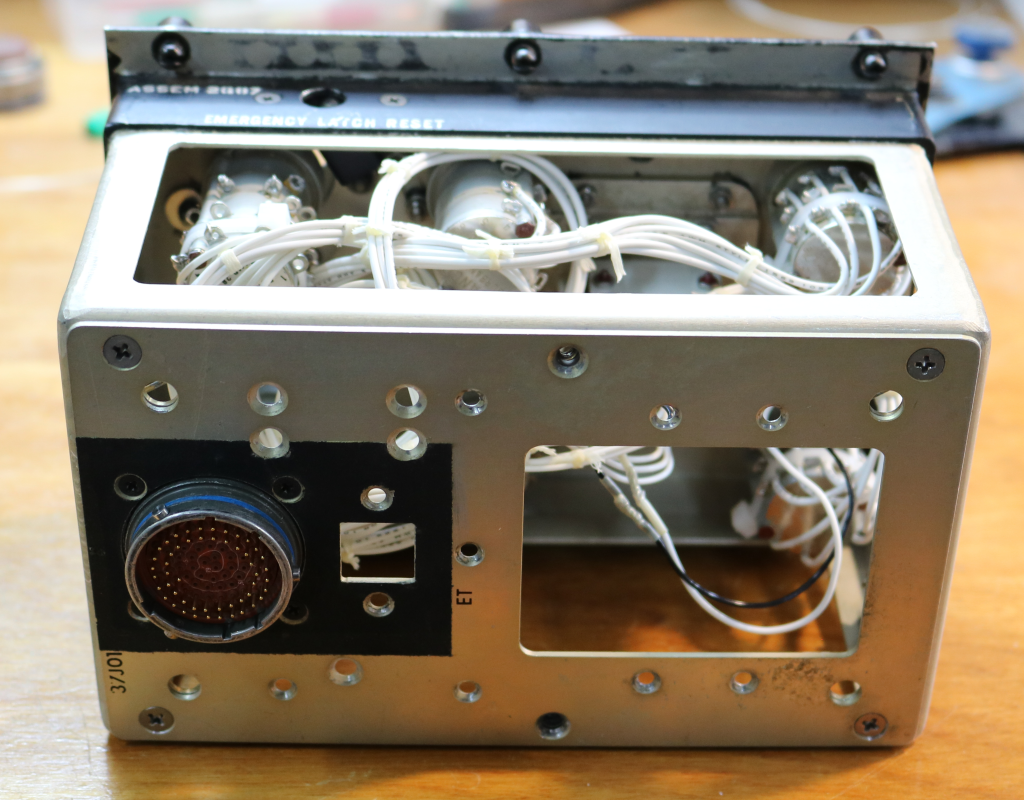

Now the back plate gets mounted. In rewiring the panel, it uses 52 pins on the original Cannon connector:

Now it’s ready for the edge-lit panel and knobs to be installed. Maintainers may spot a problem in this view. 🙂

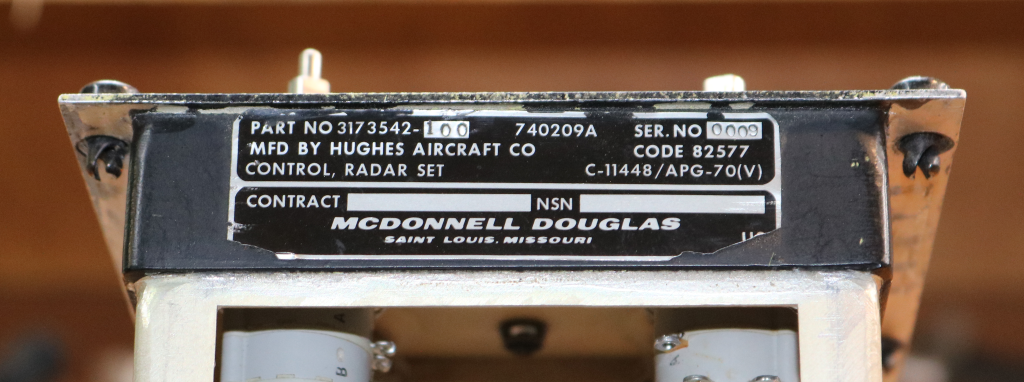

This particular APG-70(V) radar happens to be serial number 0009…

With the knobs back on…

Finally, here it is with the rear shell cover back on:

Here’s a pile of the extra bits that I didn’t need…

The next thing I need to do is craft the wiring harness that connects the APG-70(V) panel to the main bulkhead Cannon plug. I’m going to look into either building or buying some kind of automated wire measuring/cutting tool. There’s 52 wires for this panel – it makes for a very tedious work session when most of your time is consumed by measuring and cutting wire…

BTW, if anyone knows how to force WordPress to stop imposing 1:1 aspect ratios on images, please let me know in the comments.